Blog Element

Edge banding: All you need to know & its benefits

Edge banding: All you need to know & its benefits

What is Edge Banding and its uses?

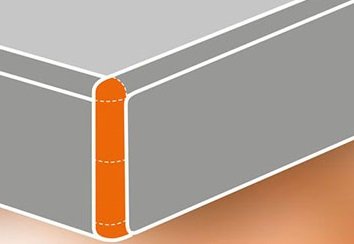

The process of sealing the raw, exposed edges of wood panels with lipping is called edge banding. Edge banding or edging has wide use in furniture making process; thus, making lipping is one of the critical sorts for materials for the furniture sector. Edge banding is also commonly used in carpentry as an end process to tidy up rough edges and ensure that the finished product is durable and constructed to a high standard.

If you have observed furniture being made, you might have noticed that the wood panels have a raw, exposed edge when cut to size. If left unprotected, this natural edge can pose severe problems for the furniture. The exposed edges of the wood panel allow moisture to seep in, making them warp and become uneven or swell, significantly reducing the furniture’s life span. It is also very damaging to appearance.

So, edge banding was created to address the problem. Edge banding protects the wooden panels in your furniture from moisture, thus reducing the effects of atmospheric humidity and liquid spills.

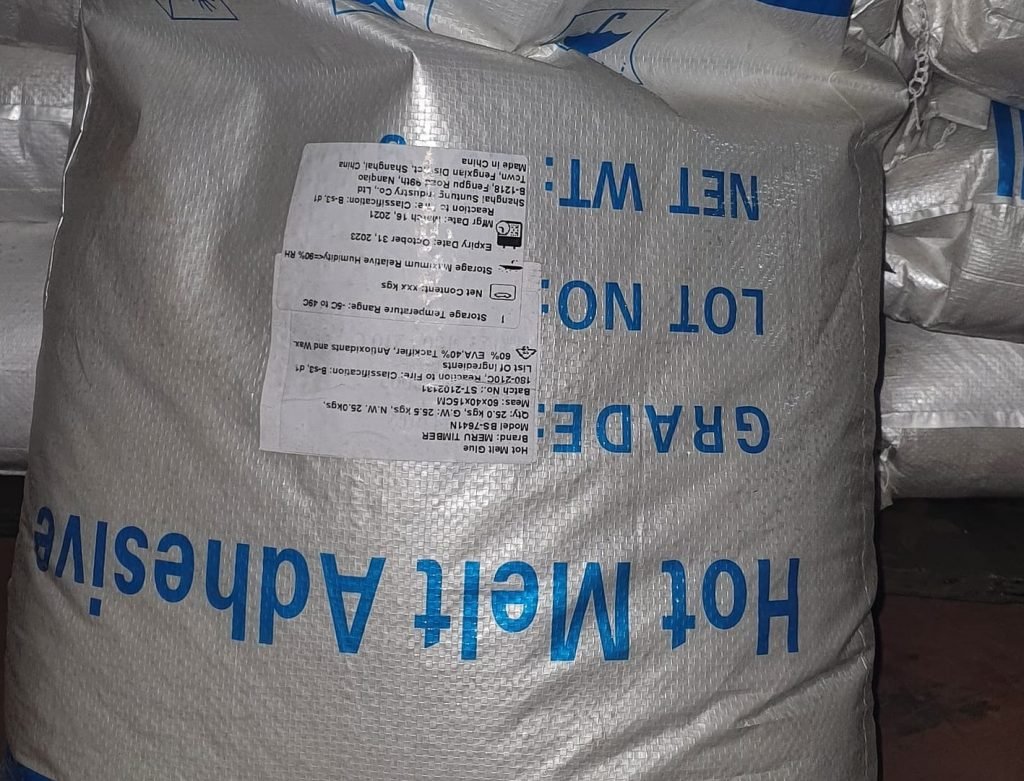

What is lipping or edge band?

Typically, a lipping or edge band is a thin tape of impermeable PVC, acrylic, or ABS material cut to fit the size of wood-based panel materials such as plywood, particleboard, or MDF. The lipping is then applied to the exposed edge using a strong adhesive. Commercially, edge banding is completed using industry-grade machines called edge banders and a hot-melt adhesive. For flatpack and modular furniture, the material used is mostly PVC, which is easy to fix and has a long life.

Lipping can be sourced in 200 metres rolls, and the thickness of the tape may vary. The width will also be quite different, depending upon the requirement of the customer. At Meru Timber, edge banding is available in various thickness ranges ranging from 0.45mm, 1mm, and even beyond that.

Thicker lipping is used in high-traffic and commercial settings because it provides greater resilience and impact resistance. For example, doors and drawer fronts may require a thicker 1mm PVC lipping for maximum impact resistance. Typically, a lipping or edge band is a thin tape of impermeable PVC, acrylic, or ABS material cut to fit the size of a wood panel. The lipping is then applied to the exposed edge using a strong adhesive.

How Does Edge Banding Protect The Furniture?

Modular furniture is made using wood-based panels. As such, the wood is handled and made resistant to moisture by treatments. Nevertheless, wood has a natural inclination to absorb moisture. This trend cannot be eradicated – it can only be reduced. The lipping protects the wooden panels in your furniture from moisture, therefore reducing the effects of atmospheric humidity and liquid spills. That means that the strength and durability of the wood increase. So, the next time you spill the tea on your table and it drips down the edge, thank the edge banding for protecting the wood.

Notably, edge banding serves both functional and aesthetic purposes. Functionally, lipping performs some essential duties for your furniture. First, it holds moisture out, serving as a de facto seal on the edge of the core material. Second, edge banding increases strength and resilience by providing shock protection. Aesthetically, edge banding covers unsightly rough edges and creates a glossy finish to match your tops and sides. You can also develop radial edges to soften sharp angles.

Are There Different Lipping For Different Materials?

There are various edge banding materials available on the market. Edge band tape can be made from PVC, ABS acrylic, PP, PMMA, PET, Laser, wood or wood veneer. But, we will focus on two common materials: PVC and ABS. PVC is the most popular material for edge banding.

PVC- PVC edge banding

PVC (polyvinyl chloride) lipping materials are made from thermoplastic gum and are soft and long-lasting. PVC lipping is most popular in the construction of Laminated And Melamine cabinets and furniture. PVC Lipping is noted for its wide variety of colour matches to Laminate and Melamine board manufacturers. With Europe-style modular cabinets on the rise, it is not uncommon to see cabinets with glossy or colourful finishes. Pigments and other materials are added to produce ostensibly endless edge banding colours, textures and natural wood grains. You are assured of finding a match once you choose your Board laminate!

PVC Edge bands or lipping

PVC edge banding is very popular for modular furniture. It is incredibly durable, simple to fix, and has an extremely long life. Therefore, the PVC edge band is the most preferred edge band model. The material is impermeable, which means that it significantly reduces water absorption.

Furthermore, modular furniture comes in a much wider variety of colours and shades than the possibilities available with real natural wood. PVC lipping can be produced to resemble your modular panel’s exact shade and finish, thus creating a seamless look. Also, PVC is easier to use on curved surfaces than natural wood bands.

So, in essence, the main reasons that PVC is such a popular choice for edge banding are:

- It is inexpensive;

- PVC is durable;

- It Boasts a long life; and

- It doesn't require any finishing process;

Cons for the use of PVC:

- You can't recycle it;

- It doesn't biodegrade;

- Once it's blemished; and

- You can't refinish it.

ABS Edge bands or lipping

ABS (acrylonitrile butadiene styrene) shares most PVC characteristics, but ABS is lower in density and does not include chlorine in its composition. Edge bands made of ABS are eco-friendly, recyclable and thermally resilient, meaning they are safe to incinerate. Lipping made of these materials are available in various colours, finishes and textures, offering you the versatility to pick a colour that best resembles your interior.

Finding the Perfect Edge banding

Whether you are a Fundi or DIY hobbyist looking for a quality edge, banding can require extra effort to achieve the look and value of your furniture. That is why you should seek professionals for their expertise and guidance in selecting the correct width, thickness, and colour shed.

There are a variety of lipping tapes available in the market, from pre-glued ones to 3D acrylic tapes:

- The thickness of – 0.45mm, 1mm (Recommended), 2mm and 3mmm

- Board thickness – 22mm, 27mm, 45mm, 54mm and 60mm

- Materials – Solid colours like – White, Light Grey, Dark Grey, Red, Green, e.t.c

- Materials – Wood Grain Colours – African Wenge Esperanza Oak, Cherry, Zalzach Beech e.t.c

Edge Banding at Meru Timber

We at Meru Timber can assist you with making those critical selections! We use top-quality, commercially available lipping with 90 different colours currently in stock. Additionally, we offer a diverse range of finishes and patterns to choose from – You name it; we have got you covered. And, if it’s pre-finished you’re looking for, we’ve got that too! The consistency of our products speaks for itself, and we are eager for you to notice our quality. Our PVC lipping materials are designed to match current popular melamine boards such as Timsales, Comply, PG Bison and Rai plywood. We aim to offer a one-stop shop and make your life easy…

Your Cost Considerations

Generally speaking, we recommend PVC lipping for projects where budget is the primary factor. That is not to say there is anything wrong with this material—far from it. There are just fewer levels in the production process, and the raw material is less costly. We consider this a premium solution with more steps required in the production process.

Using the right lipping for a particular material is essential to ensuring strength, durability, and precision. We recommend 1mm lipping for PVC because it runs cleaner, faster, and with superior adhesion. Thus, an added benefit is a smooth radius and nice, soft-looking furniture.

EDGE BANDING WITH HOT MELT ADHESIVE

Edging adhesive, also known as hot-melt glue, is a thermoplastic adhesive. A suitable adhesive is essential to ensure that your edge banding goes on and stays on and that you don’t make a mess of your project. However, using the wrong glue in the wrong way could spell disaster!

We choose to use a hot melt glue for our adhesive solution because it’s user-friendly and provides an excellent seal. We apply the glue to the edge while still hot and then use the banding, pressing it to the side.

The two main hot-melt glue choices are EVA (Ethylene Vinyl Acetate) and PUR (Polyurethane). Each has advantages and disadvantages, depending on your project and the material you are working with.

- EVA Adhesive. EVA adhesive is a multipurpose hot melt glue used in various applications. It is suitable for all edge banding, including PVC, Melamine, ABS, Acrylic, and wood veneer. It’s the most affordable end of the market, has fairly standard water and heat resistance, and is easy to work with and clear up after.

- PUR adhesive. Polyurethane (PUR)- based hot melt glue hardens when dry and cannot be remelted. It forms a powerful bond quickly, leaving little room for mistakes and the need to work fast. Some can set in seconds; the full cure time is 24 hours.

Machinery is used in the process of Edge Banding

The machine that is used for this process is called an edge bander. The Edge bander machine applies the lipping to the raw edges of the wood panels with hot-melt glue. Edge banding machines can process lipping up to 3 mm thick and up to 50 mm wide. The ends are trimmed flush and bent to cover the wood and do not have any sharp corners at the edges. Any excess adhesive is scraped off, and the finished edge is buffed to give a perfect, seamless finish.

At Meru Timber, we use State-of-the-art machinery that improves the glue edge and squares it up perfectly. One of them is Casadei Edge banding machines – Italian technology and another Industrial edge banding machine from Europe, Capable of grooving and corner rounding.

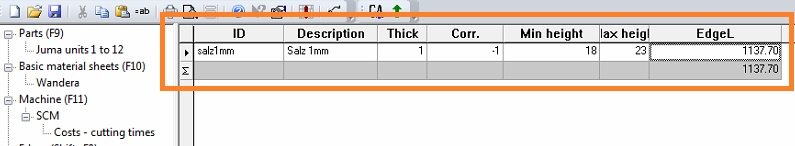

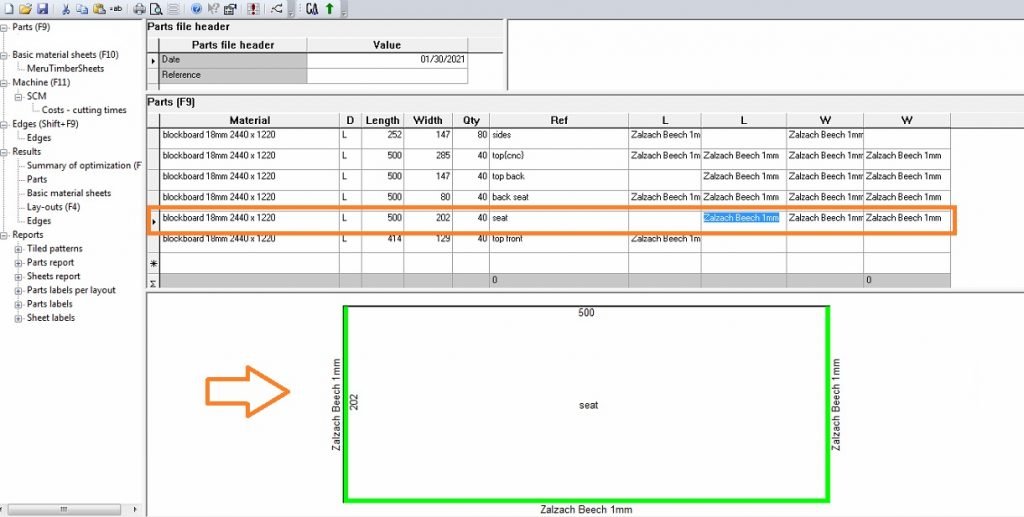

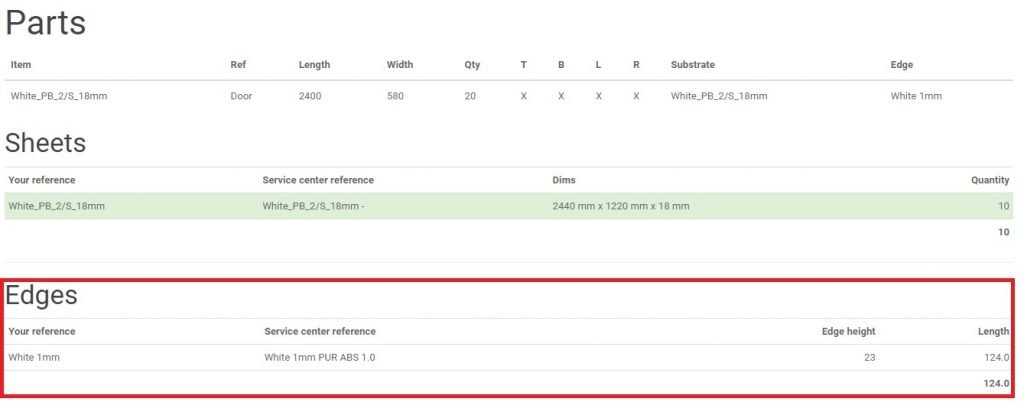

Additionally, we’ve invested in top-of-the-line Cutting Optimization software to calculate and determine the linear Metres of lipping required for your entire Project.

When generating your cutting list, there is no need to subtract edge banding thickness; our software will automatically provide you with the finished size.

The size of the part is automatically adjusted to accommodate the thickness of the lipping.

Learn how to manage your cutting list successfully on Meru Timber’s online cutting list platform. Then, with a single click of a button, you can get the quantity of edge banding material required for your entire Kitchen or wardrobe project!

A Quick start video on how to us Meru Timber cutting list platform is as below. Remember, its absolute Free to use our online cutting list platform!

A local carpenter/in-house fundus may not have the capacity and know-how within their reach. That’s why there is a distinction between commercial modular and carpentry edge banding.

If you want the best kitchen material, use MDF and particle boards.

Videos: Edge Banding Basics

Here is a video to help you visualize the process on an industrial scale. Using a fully automated machine for excellent flexibility and easy adjustment reduces production time and gives the best output.

At Meru Timber, we provide first-class edge banding processing solutions for various processes and materials with extreme accuracy and precision in no time.

We believe this article has provided insight into the edge banding process. If you have further questions about edge banding, comment; we will be happy to answer your queries.